The Dawn of Cognitive Agriculture

The global food system is at a critical juncture. Faced with a rapidly growing population, diminishing arable land, unpredictable climate change, and increasing demand for locally sourced, high-quality produce, the traditional methods of agriculture are proving unsustainable. For decades, the solution has been sought in incremental improvements—better fertilizers, more resilient seeds, and larger machinery. But the true revolution is not mechanical; it is cognitive. It is the integration of advanced Artificial Intelligence (AI) into the very fabric of food production.

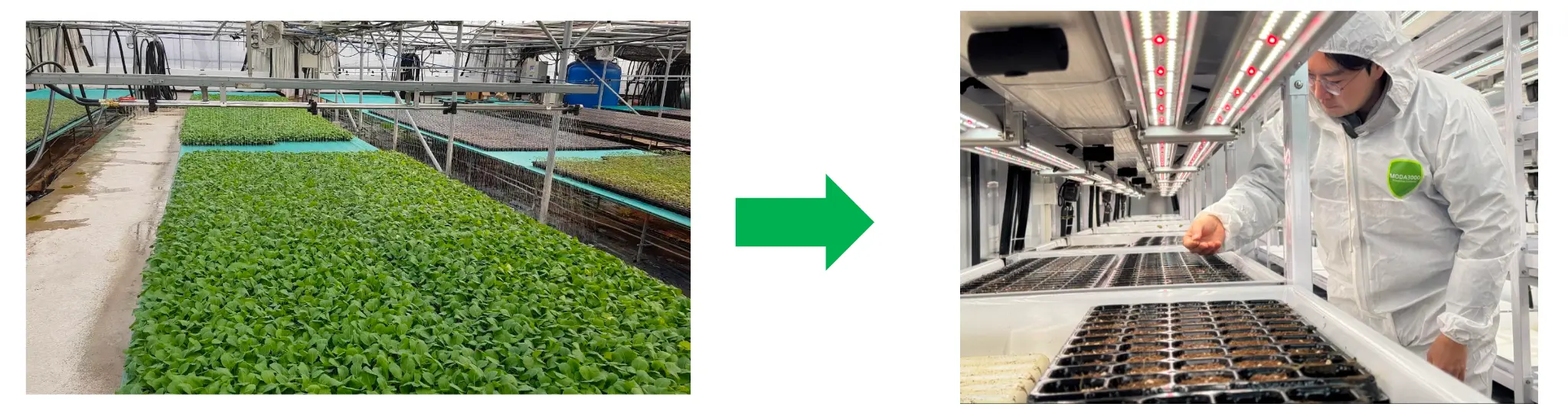

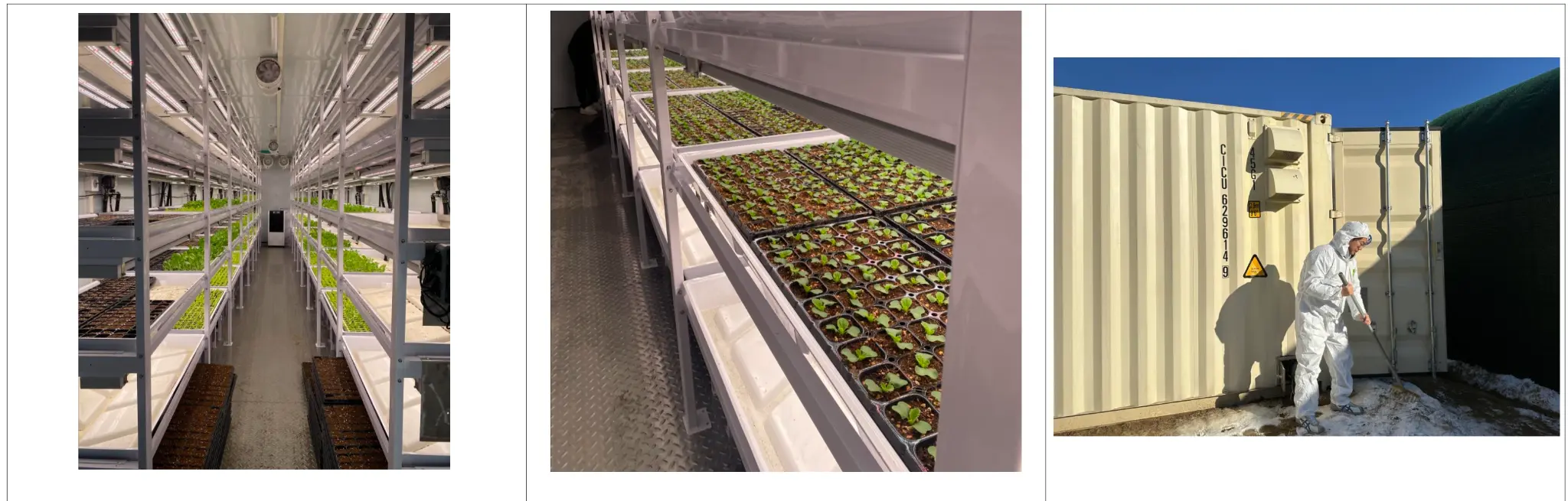

Enter Infarmight, a company that has moved beyond the concept of a “smart farm” to establish the world’s first truly Cognitive Agriculture system. Infarmight’s vertical farms are not merely automated greenhouses; they are highly sophisticated, self-optimizing biological data centers where every aspect of plant life is monitored, analyzed, and controlled by a proprietary AI stack. The company’s core innovation is not the structure of the farm, but the intelligence that runs it. This intelligence is what allows Infarmight to deliver unprecedented yields, resource efficiency, and nutritional consistency, effectively decoupling food production from the constraints of geography and climate.

The challenge of modern farming is one of complexity. A single plant’s growth is a function of dozens of interacting variables: light spectrum, nutrient composition, pH levels, humidity, temperature, CO2 concentration, and more. Managing these variables manually or with simple automation is impossible at scale. Infarmight’s AI system, which we call the “Agri-Brain,” is designed to master this complexity, transforming farming from an art based on intuition and experience into a precise, data-driven science. This is the story of how Infarmight’s technology is not just improving agriculture, but fundamentally redefining it.

The Core: Infarmight’s AI Architecture

Infarmight’s technological advantage stems from its integrated, three-layer AI architecture: the Sensor Layer, the Cognitive Layer, and the Robotic Layer. This holistic system ensures that data collection, decision-making, and physical execution are seamlessly coordinated.

The Sensor Layer: The Farm’s Nervous System

The foundation of the system is a dense network of sensors that act as the farm’s nervous system. Unlike traditional farms that rely on periodic, localized measurements, Infarmight’s facilities are saturated with continuous, real-time data streams. This includes:

- Environmental Sensors: Monitoring temperature, humidity, CO2, and air flow at multiple vertical points.

- Hydroponic Sensors: Tracking nutrient solution composition, pH, electrical conductivity (EC), and dissolved oxygen.

- Plant-Level Sensors: Utilizing non-invasive techniques like thermal imaging and chlorophyll fluorescence to assess plant stress and photosynthetic efficiency.

The Cognitive Layer: The Agri-Brain

This is the heart of Infarmight’s innovation. The Cognitive Layer is a cloud-based platform running a suite of specialized deep learning models. It ingests petabytes of data from the Sensor Layer, cross-references it with historical growth data, and executes complex predictive and prescriptive analytics.

The Agri-Brain is composed of several key modules:

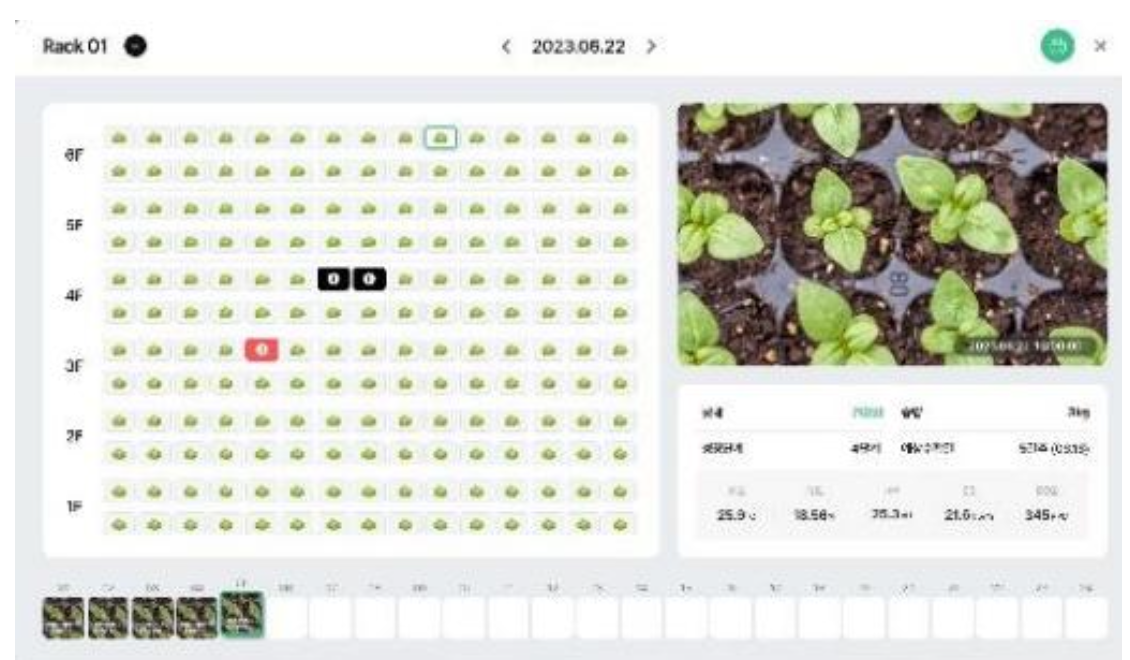

- Phenotyping Engine: Uses computer vision to track the physical characteristics (phenotype) of every single plant, from leaf size to color saturation.

- Predictive Yield Model (PYM): A time-series forecasting model that predicts the exact harvest date, yield weight, and nutritional profile of crops weeks in advance.

- Prescriptive Control System (PCS): The action-oriented module that translates predictions into commands for the Robotic Layer, adjusting light, climate, and nutrient delivery.

The Robotic Layer: The Farm’s Muscles

The final layer is the physical execution system, which consists of custom-designed robotics and automation hardware. These systems receive commands from the PCS and execute them with sub-millimeter precision, ensuring that the AI’s decisions are perfectly implemented.

Precision Phenotyping and Computer Vision

One of the most significant technological leaps made by Infarmight is in the field of precision phenotyping. In traditional farming, a farmer assesses a crop’s health by visually inspecting a small sample. Infarmight, however, uses advanced computer vision to create a Digital Twin for every single plant in the facility.

High-resolution, multi-spectral cameras mounted on gantry systems traverse the vertical racks, capturing images of every plant multiple times per day. These images are not just visible light; they include near-infrared and other spectral bands that reveal information invisible to the human eye.

The AI’s computer vision models are trained on millions of images of healthy and stressed plants. They can instantly detect:

- Early Disease Onset: Identifying subtle changes in leaf texture or color that indicate a fungal or bacterial infection days before a human could notice.

- Nutrient Deficiencies: Pinpointing which specific nutrient (e.g., nitrogen, potassium, iron) is lacking based on the plant’s spectral signature.

- Growth Rate Anomalies: Flagging plants that are growing slower or faster than the predicted model for their specific cultivar and growth stage.

This level of granularity allows for individualized plant care. If a single plant shows signs of stress, the system can isolate its tray and adjust its micro-environment (e.g., localized nutrient boost or light spectrum change) without affecting the thousands of other plants around it. This is the ultimate realization of precision agriculture.

The Algorithmic Farmhand: Robotics and Automation

The physical manifestation of the Agri-Brain’s intelligence is its fleet of autonomous robotic systems. These robots are not pre-programmed to follow a fixed routine; they are dynamic, AI-guided farmhands whose actions are optimized in real-time by the Cognitive Layer.

AI-Driven Robotics

Infarmight’s robotic systems handle all labor-intensive tasks, including:

- Seeding and Transplanting: High-speed, vision-guided manipulators place seeds and transfer seedlings with extreme accuracy, minimizing damage and maximizing planting density.

- Automated Harvesting: The computer vision system identifies plants that have reached the optimal maturity profile (based on size, color, and predicted flavor compounds). Robotic arms then perform a precise, non-destructive harvest, ensuring only the best produce is picked at the perfect moment.

- Maintenance and Inspection: Robots continuously move through the racks, performing tasks like cleaning, sensor calibration, and isolating stressed plants for closer inspection.

Pathfinding and Reinforcement Learning

The efficiency of these robots is governed by sophisticated algorithms. The system uses *A search algorithms and dynamic pathfinding** to calculate the most efficient routes for the gantry robots, minimizing travel time and energy consumption.

Furthermore, Infarmight employs Reinforcement Learning (RL) to continuously improve robotic performance. The RL models are rewarded for metrics like “time to harvest,” “energy consumption per cycle,” and “planting accuracy.” Over time, the robots learn to execute their tasks more efficiently than any human operator could, adapting to minor changes in the farm layout or plant density. This continuous learning loop ensures that the farm’s operational efficiency is always increasing, a key factor in achieving economic viability for vertical farming.

Environmental Control and Predictive Modeling

The controlled environment of a vertical farm is its greatest asset, but also its greatest challenge. Maintaining the perfect climate for thousands of plants simultaneously requires a level of control that is beyond human capability. Infarmight’s AI excels here, using Deep Learning to manage the farm’s microclimate with unparalleled precision.

Deep Learning for Climate Control

The system treats the entire farm as a complex, multi-variable thermodynamic system. The Deep Learning models ingest data from hundreds of environmental sensors and predict the effect of every control action (e.g., turning on a fan, adjusting a chiller, increasing CO2 injection) on the entire environment.

Key AI-controlled parameters include:

- Temperature and Humidity: Maintaining optimal vapor pressure deficit (VPD) for maximum transpiration and nutrient uptake.

- Light Spectrum and Intensity: Adjusting the LED light recipes in real-time to promote specific plant characteristics, such as higher antioxidant levels or improved flavor profiles. The AI can even simulate diurnal cycles and seasonal changes to “trick” the plants into desired growth patterns.

Predictive Yield Modeling (PYM)

The Predictive Yield Model is one of Infarmight’s most valuable technological assets. By combining historical growth data, real-time sensor readings, and external factors (like energy cost forecasts), the PYM can forecast the exact output of the farm with an accuracy exceeding 98%. This predictive capability is transformative for the supply chain, allowing Infarmight to:

- Optimize Planting Schedules: Ensuring a steady, predictable supply of produce year-round.

- Minimize Waste: Harvesting only what is needed, precisely when it is needed.

- Maximize Profitability: Adjusting environmental inputs to meet market demand and energy cost fluctuations.

The following table illustrates the dramatic difference in control and efficiency achieved by Infarmight’s AI-driven system compared to a traditional, non-AI-controlled greenhouse:

| Feature | Traditional Greenhouse | Infarmight AI-Controlled Farm |

|---|---|---|

| Environmental Control | Manual/Thermostatic; ±3°C fluctuation | AI-Driven; ±0.5°C fluctuation |

| Water Use Efficiency | High evaporation; 10-20 L/kg of produce | Closed-loop system; < 1 L/kg of produce |

| Pest/Disease Detection | Human visual inspection; late-stage detection | Computer Vision; sub-symptomatic detection |

| Yield Predictability | Seasonal, highly variable (±15%) | Year-round, highly accurate (>98%) |

| Nutrient Management | Batch dosing; fixed recipes | Real-time micro-dosing; dynamic recipes |

Data-Driven Nutrient Management

In hydroponic and aeroponic systems, the nutrient solution is the lifeblood of the plant. Managing this solution is a complex chemical balancing act, and Infarmight has turned it into an algorithmic masterpiece.

Sensor Fusion and Real-Time Analysis

The system employs a technique called sensor fusion, where data from multiple sources—EC, pH, dissolved oxygen, and specific ion sensors—are combined and analyzed by the AI. This provides a far more accurate and complete picture of the nutrient solution than any single sensor could offer.

The AI constantly monitors the plant’s uptake rate by tracking the difference between the input and output nutrient solution. If a plant is rapidly consuming a specific element (e.g., calcium during a growth spurt), the AI immediately identifies the need and adjusts the nutrient delivery.

AI-Optimized Nutrient Recipes

Infarmight maintains a vast library of “nutrient recipes” for different cultivars and desired outcomes. However, the AI does not simply follow a static recipe. It uses a Bayesian Optimization model to continuously refine the recipe in real-time.

For example, if the goal is to maximize the concentration of a specific phytonutrient (like Vitamin C or a particular antioxidant), the AI will run micro-experiments on small batches of plants, slightly altering the nutrient mix and observing the resulting chemical composition of the harvested produce. The model then uses the successful experiments to update the global recipe, ensuring that the entire farm is always operating at the chemical frontier of plant optimization. This process of continuous, automated experimentation is what allows Infarmight to produce crops with superior flavor and nutritional density.

Nutrient Micro-Dosing

The Prescriptive Control System (PCS) implements Nutrient Micro-Dosing. Instead of adding large batches of nutrients, the system adds precise, minute quantities of individual elements (Nitrogen, Phosphorus, Potassium, and micronutrients) multiple times per hour. This ensures that the plants always have access to the exact concentration of nutrients they need, minimizing nutrient shock and maximizing uptake efficiency. This hyper-precise control is a key reason why Infarmight’s water use efficiency is nearly 99% better than traditional farming.

Economic and Environmental Impact

The technological advancements at Infarmight translate directly into profound economic and environmental benefits, demonstrating that high-tech agriculture is not just a scientific curiosity but a necessity for a sustainable future.

Resource Efficiency: The AI Dividend

The AI-driven control systems are fundamentally about efficiency. By eliminating waste and optimizing every input, Infarmight achieves resource metrics that are unattainable in any other form of agriculture:

- Water: The closed-loop hydroponic system, combined with AI-optimized transpiration control, results in up to 95% less water usage compared to field farming for the same crop.

- Land: Vertical stacking and high-density planting, guided by AI to prevent overcrowding, result in a land use efficiency that is 300 to 400 times greater than conventional farming.

- Energy: While vertical farming is energy-intensive, Infarmight’s AI minimizes consumption through smart scheduling of LED lighting (taking advantage of off-peak electricity rates) and optimizing HVAC systems to reduce cooling load. The Predictive Yield Model also ensures that energy is only spent on crops that will be successfully harvested.

Eliminating Waste and Carbon Footprint

AI’s ability to predict yield and harvest timing with near-perfect accuracy virtually eliminates post-harvest waste, a major problem in the traditional supply chain. Furthermore, by locating farms in or near urban centers, Infarmight drastically reduces the “food miles” associated with transportation.

The AI-managed supply chain ensures that produce is harvested, packaged, and delivered within hours, not days, leading to fresher, longer-lasting products for the consumer and a significantly lower carbon footprint per unit of food produced.

The Future of Food: Infarmight’s Roadmap

Infarmight is not resting on its current technological achievements. The company’s R&D roadmap is focused on pushing the boundaries of what is possible in controlled environment agriculture, moving toward a future of fully autonomous, self-optimizing food networks.

Current R&D Frontiers

- Hyper-Spectral Imaging and Metabolomics: The next generation of the Phenotyping Engine will incorporate hyper-spectral imaging, which can detect hundreds of narrow light bands. This will allow the AI to non-invasively measure the metabolomic profile of a plant—its exact chemical composition, including flavor compounds, vitamins, and antioxidants—in real-time. This will enable the AI to “tune” the flavor and nutritional content of produce to specific consumer demands.

- Genetic Optimization via AI: Infarmight is using its vast dataset of plant growth under controlled conditions to inform geneticists. The AI can identify which genetic traits respond best to specific environmental inputs, accelerating the development of new, high-performing cultivars optimized for vertical farming. This is AI-guided plant breeding.

- Decentralized Autonomous Farm Networks: The ultimate vision is a network of Infarmight facilities that communicate and learn from each other. If a farm in New York discovers an optimal nutrient recipe for a specific basil strain, that knowledge is instantly shared and implemented by all other farms globally. This creates a single, continuously improving global “Agri-Brain.”

Conclusion: Engineering Life

Infarmight’s revolution is not just about growing food indoors; it is about applying the most advanced principles of computer science, data engineering, and robotics to the biological process of growth. By treating the farm as a complex, self-optimizing system, Infarmight has created a model for food production that is more efficient, more predictable, and more sustainable than anything that has come before.

The AI is the farmer, the scientist, and the engineer, all rolled into one. It is a testament to the power of technology to solve humanity’s most pressing challenges. Infarmight is not just growing vegetables; it is engineering life, and in doing so, it is laying the foundation for the future of food.